For more than 20 years, INNIO Group has worked with hydrogen, recognizing it as a future energy source. With this technological expertise, INNIO Group is preparing to gradually convert its Jenbacher gensets to hydrogen operation. Following the certification of the Jenbacher Types 4 and 6 engines, TÜV SÜD also has certified the hydrogen concept for Type 9. For Jenbacher customers, certification means greater investment security.

INNIO Group is the first manufacturer in the world to be able to offer its customers engine-based energy solutions based on an H2-Readiness concept certified by TÜV SÜD. The certification applies to both new plants and the retrofitting of existing Jenbacher plants to run on 100% hydrogen. In October 2023, the first step of the TÜV SÜD certification confirmed H2-Readiness of INNIO Group’s plant concept for its hydrogen product lines based on Jenbacher Types 4 and 6. Certification for Type 9 followed in summer 2024. All certifications are based on the TÜV-SÜD “Certification Guideline H2-Readiness of Gas Engine Power Plants.”

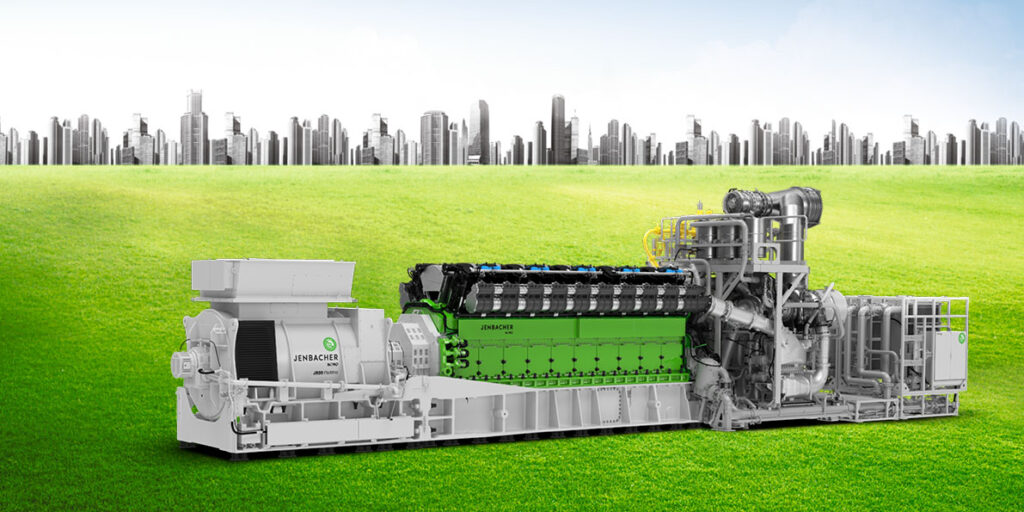

4, 6, and 9

Jenbacher engine types with H2-Readiness certificate from TÜV SÜD

100%

Hydrogen operation

10/2023

Certification of Types 4 and 6

07/2024

Certification of Type 9

Holistic certification

Essentially, all Jenbacher engines that are supplied by INNIO Group as “H2-ready” can be operated using a hydrogen admixture of up to 25% by volume in the pipeline gas. However, the objective of the TÜV certification was operation using 100% hydrogen, for which INNIO Group has developed a stand-alone Jenbacher engine concept. This concept includes a fuel system with port fuel injection designed specifically for the properties of pure hydrogen, a comprehensive engine control unit update, as well as various other adjustments.

The H2-Readiness concept by TÜV SÜD represents a holistic certification. It incorporates the impact of a fuel regime change from natural gas to 100% hydrogen for an engine power plant as a whole and, in the process, considers all relevant components and systems – both for new plants and those already in operation.

The following key aspects were considered:

- Plant-based fuel supply

- Gas engine

- Plant-based exhaust system

- Auxiliary and secondary systems

- Buildings

- Heating, air conditioning, and ventilation systems (HVAC)

- Plant-based measurement and control equipment

- Plant performance

- Explosion protection concept

- Fire protection concept

- Hazard and risk assessment

- Conformity

In awarding the certificate, TÜV SÜD confirms that INNIO Group met the requirements for these key aspects set out in the TÜV guideline and presented a coherent concept for safe and reliable plant operation using 100% hydrogen.

Investment security for Jenbacher customers

Customers want to ensure their plants don’t become “stranded assets.” For this reason, the ”Ready for H2” Jenbacher engine conversion concept constituted a substantial part of the certification scope. The certification by TÜV SÜD substantiates investment security when purchasing Jenbacher energy solutions, as the engines can be reliably converted to run on hydrogen at a later date.

We are pleased that following Types 4 and 6, Type 9 of our Jenbacher hydrogen product line now also has been certified as H2-ready by TÜV SÜD. These independent certificates mean that we can now offer even greater investment security to our customers who are opting for sustainable, hydrogen-based energy solutions.

Dr. Andreas Kunz, Chief Technology Officer of the INNIO Group