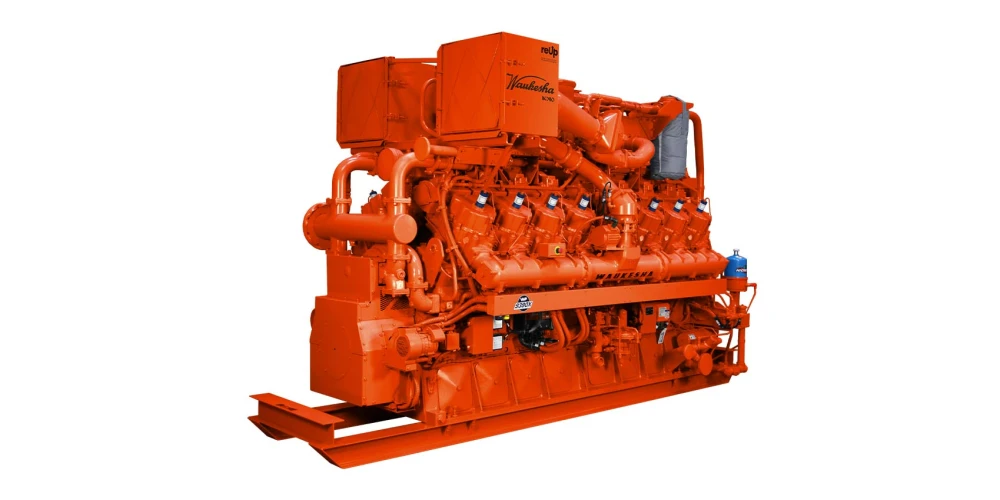

INNIO Group announces its newest Waukesha VHP P9390X engine upgrade designed for simpler operation and increased reliability. The upgrade provides operators with advanced engine technology, extending the life of the equipment by 60% while lowering downtime and reducing emissions across various operating conditions. The VHP P9390X has a power output of 1980 BHP, operates at speeds between 900-1,200 rpm, and can handle a 10% overload capacity.

Operators can achieve Waukesha VHP P9390X engine performance by exchanging their existing VHP P9390 engine for a Waukesha reUp factory remanufactured swing engine or by applying an upgrade kit in-place during their next overhaul of their VHP P9390 GSI engines.

The engine update includes:

- ESM2 controls: This single integrated engine control system offers data trending and analysis, troubleshooting guides and manuals, and remote monitoring capabilities.

- xCooled cylinder heads: Providing up to a 60% longer lifespan and up to 40% cooler valve temperatures, xCooled cylinder heads can reduce parts cost and downtime, while a redesigned exhaust path decreases hot spots.

- Series Four pistons: With reduced oil consumption by as much as 67%, Series Four pistons can bring significant cost savings.

- Optional emPact emission control system: Offered in standard configurations to match local emissions regulations, the emPact catalyst is controlled and monitored from the ESM2 HMI, allowing automatic adjustments to help achieve and maintain emissions compliance.

- Advanced crankcase breather: With the advanced breather, the Waukesha engine experiences up to 90% less oil blow-by, less oil contamination of the three-way catalyst, reduced coking for fewer oil leaks, and 8,000-hour service intervals.

Up to 60%

increase in equipment lifespan

8,000-hour

service intervals

90%

less oil blow-by

VHP P9390 engines

found in 40+ countries

The Waukesha VHP P9390X engine upgrade is an excellent solution for customers planning a major overhaul in the next year or two, for customers with emission compliance concerns, and for those with growing digital operations. They’ll lower operating costs and downtime while meeting emissions regulations.

Pier Parisi, vice president of Sales and Services for INNIO Group's Waukesha brand