• Two Jenbacher J620 gas engines form the heart of a new combined heat and power plant in Ottersberg, Lower Saxony

• Investment increases electrical efficiency to 44.2%

• Biogas represents an excellent supplement to wind and solar power

JENBACH (Austria) — October 24, 2019 — As early as 2005, when most biogas operators did not even dare to think of combined heat and power plants (CHP) with a capacity of over 300 kilowatts (kW), the biogas pioneer BENAS GmbH invested in five INNIO Jenbacher J320 gas engines with a total capacity of 5.24 megawatts (MW) for its plant in Ottersberg near Bremen. Today, the companies announced that BENAS has enlarged this CHP plant through the addition of two Jenbacher J620 gas engines with a capacity of 3.05 MW each and has thus created the largest single biogas engine complex in Germany.

The BENAS executive management are regarded as energy turnaround visionaries and pioneers among Germany’s biogas operators. With this investment, BENAS has not only increased the electrical efficiency of its plant by 7.2 percentage points, but also reduced its raw material needs and cut the required crop acreage and transport costs by 19.5%. In absolute terms, BENAS’ energy corn demand, which provides part of the plant’s biogas supply, has been cut by around 15,500 tonnes per year and the area cultivated for this purpose by around 370 hectares. As was originally the case, the new Ottersberg plant is operated solely using renewable raw materials and dried poultry manure.

As Jürgen Heitmann, the BENAS GmbH founder, explains, “Twenty-five years ago, we were among the first farmers to build a biogas plant. And now as then, we wish to contribute to the energy transformation, make our company more environment-friendly and naturally enough, earn a little money as well.”

With a workforce of 45, BENAS grows energy plants at three locations on a total of 3,300 hectares. The biogas plant, which was designed and built by the company itself, currently disposes over a fermentation volume of 43,000 m3, gas storage capacity of 33,000 m3 and net installed electricity output of 11.35 MW. In addition, BENAS operates a gas treatment plant in which 1,200 m³/h of biogas is upgraded to natural gas quality.

The investments in the new plant mean that Ottersberg can now generate 28,000 MWh of electricity annually. This will be both fed into the grid and employed to heat a fiber processing plant, which has been developed jointly with Gesellschaft für Nachhaltige Stoffnutzung mbH in Halle.

According to Christoph Heitmann, the BENAS CEO, who was responsible for the planning and construction of the new CHP plant, “The decisive reason for the investment was the enormous improvement in the efficiency of combined heat and power plants during the past 15 years.”

In the course of the building work, the heat supply emanating from both cooling water and exhaust was fully automated and adapted to match the new overall system. As a result, the output of the fiber treatment plant was raised by 50% and simultaneously, a high degree of safety was achieved by means of linked process control technology.

Owing to the operational flexibility that it offers, bioenergy is seen as being of major importance to the energy turnaround. Biogas plants can start up quickly and are therefore able to compensate for grid fluctuations.

Indeed, as Norbert Hetebrueg, General Manager for Central and Northern Europe at INNIO Jenbacher, makes clear, “As opposed to solar or wind power, biogas is an energy source with storage capabilities that can be used to produce power or heat at any time of the day and year regardless of whether the sun is shining, it is raining or it is storming. Consequently, INNIO’s fuel-flexible Jenbacher gas engines constitute an integral part of the global energy transformation and can contribute to power supply security.”

Agriculture generates resources on a daily basis

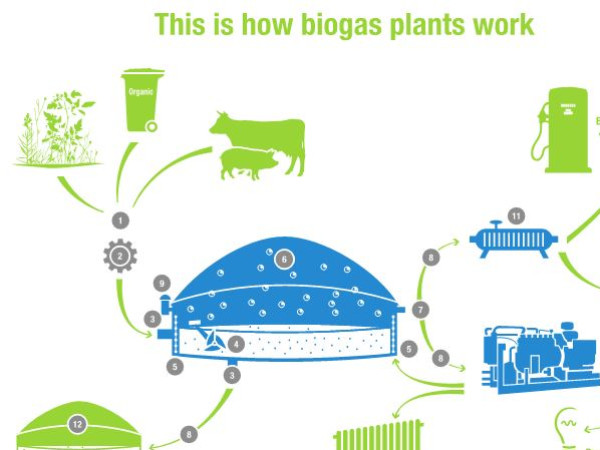

Biogas is flammable and results from the fermentation of residues containing biomass such as sewage sludge, livestock manure or plant waste. A large percentage of these raw materials and in particular, livestock manure and plant waste, emanate from standard, day-to-day farming. As a result, the agricultural sector offers the greatest potential for the production of biogas.

The average heating value of a cubic meter of biogas is roughly equal to that of 0.6 liter (l) of fuel oil. Therefore, 1 ton (t) of organic waste material and 3 t of liquid or solid manure can generate an amount of biogas with a heating value equivalent to that of 60 l of fuel oil or 120 kWh of electricity. At the same time, carbon dioxide emissions are reduced by 200 kilograms.

Biogas achieves its maximum electrical efficiency and thus its optimum carbon footprint, when by means of CHP it is employed simultaneously for the production of both heat and power. Methane is its most valuable constituent and at a maximum can represent 60% of biogas volume. This is important, as the energy level of the gas increases in line with its methane content.