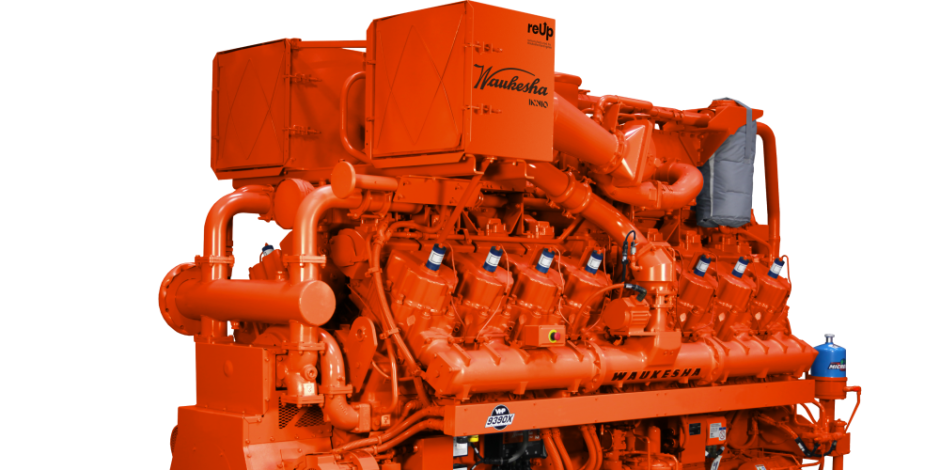

• The Waukesha VHP P9390X engine upgrade is available through the Waukesha reUp remanufacturing program for several models of VHP P9390 engines and as an upgrade kit for VHP P9390 GSI engines

• The upgrade extends equipment life, increases reliability, and reduces downtime

WAUKESHA, Wisconsin – September 5, 2024 — INNIO Group announces its newest Waukesha VHP P9390X engine upgrade designed for simpler operation and increased reliability. The VHP P9390X upgrade offers operators the latest engine technology, extending the life of the equipment by 60% while lowering downtime and reducing emissions across various operating conditions.

The VHP P9390X has a power output of 1980 BHP, operates at speeds between 900-1,200 rpm, and can handle a 10% overload capacity. It directly replaces existing VHP P9390 engines. Operators can achieve Waukesha VHP P9390X engine performance by exchanging their existing VHP P9390 engine for a Waukesha reUp factory remanufactured swing engine or by applying an upgrade kit in-place during their next overhaul.

“The Waukesha VHP P9390X engine upgrade is an excellent solution for customers planning a major overhaul in the next year or two, for customers with emission compliance concerns, and for those with growing digital operations,” said Pier Parisi, Vice President of Sales and Services for INNIO Group’s Waukesha brand. “They’ll lower operating costs and downtime while meeting emissions regulations.”

The engine update includes:

- ESM2 controls: This single integrated engine control system offers data trending and analysis, troubleshooting guides and manuals, and remote monitoring capabilities.

- xCooled cylinder heads: Offering an increased lifetime of up to 60% and up to 40% cooler valve temperatures, xCooled cylinder heads can reduce parts cost and downtime, while a redesigned exhaust path minimizes hot spots.

- Series Four pistons: With reduced oil consumption by as much as 67%, Series Four pistons can bring significant cost savings.

- Optional emPact emission control system: Offered in standard configurations to match local emissions regulations, the emPact catalyst is controlled and monitored from the ESM2 HMI, allowing automatic adjustments to help achieve and maintain emissions compliance.

- Advanced crankcase breather: With the advanced breather, the Waukesha engine gains up to 90% less oil blow-by, less oil contamination of the three-way catalyst, reduced coking for fewer oil leaks, and 8,000-hour service intervals.

INNIO Group’s Waukesha VHP P9390 engines have delivered decades of reliable performance in the harshest conditions and can be found in over 40 countries.

About INNIO Group

INNIO Group is a leading energy solution and service provider that empowers industries and communities to make sustainable energy work today. With its Jenbacher and Waukesha product brands and its AI-powered myPlant digital platform, INNIO Group offers innovative solutions for the power generation and compression segments that help industries and communities generate and manage energy sustainably while navigating the fast-changing landscape of traditional and green energy sources. INNIO Group is individual in scope, but global in scale. With its flexible, scalable, and resilient energy solutions and services, INNIO Group enables its customers to manage the energy transition along the energy value chain wherever they are in their transition journey.

INNIO Group is headquartered in Jenbach (Austria), with other primary operations in Waukesha (Wisconsin, U.S.) and Welland (Ontario, Canada). Through a service network in more than 100 countries, a team of more than 4,000 experts provides life-cycle support to the more than 57,000 engines that INNIO Group has delivered globally.

INNIO Group’s ESG strategy has been recognized and awarded by esteemed rating agencies such as Sustainalytics and EcoVadis. Additionally, the company’s near-term climate targets until 2030 have been validated by the Science Based Targets initiative (SBTi).

For more information, visit INNIO Group’s website at www.innio.com. Follow INNIO on Twitter and LinkedIn.

About Waukesha – an INNIO Group brand

INNIO Group’s Waukesha engines are at the forefront of the energy transition, providing reliable and compliant energy solutions for distributed gas compression and power generation applications. The brand’s rich and lean-burn engines, ranging from 335 hp to 5,000 hp, set an industry standard for low emissions, high reliability, and fuel flexibility.

Waukesha products are continuously upgraded to help operators stay emission-compliant without sacrificing operational excellence. These upgrades include new and remanufactured engines and parts, as well as conversion and modification kits, all of which are backed by OEM warranty and more than 115 years of engine expertise. Additionally, Waukesha digital solutions include SkidiQ, a collaborative solution with Detechtion Technologies for gas compression applications and INNIO Group’s AI-powered myPlant platform for power generation applications. Both solutions provide customers with enhanced monitoring and optimization capabilities, resulting in improved performance and reduced downtime.

The Waukesha team connects locally with its customers to enable a rapid response to their service needs, providing enhanced support through a broad network of distributors and solution providers with parts, services, and digital offerings.

Waukesha engines are engineered in Waukesha, Wisconsin, U.S., and manufactured in Welland, Ontario, Canada. To learn more about the company’s products and services, please visit INNIO Group’s Waukesha website at waukeshaengine.com or follow Waukesha engines on LinkedIn.

INNIO, Jenbacher, Waukesha, and myPlant are trademarks or registered trademarks of the INNIO Group, or one of its subsidiaries, in the European Union, the United States and in other countries. For a list of INNIO Group trademarks, please visit innio.com/trademarks. All other trademarks and company names are the property of their respective owners.

For further information please contact:

Sheila Meehan

INNIO Waukesha Gas Engines Inc.

sheila.meehan@innio.com

+1 262 422 7313